Powder Coating Services in

Marlboro & Old Bridge, NJ

Call Now To Inquire About Our Pickup & Delivery Services

ABOUT POWDER COATING

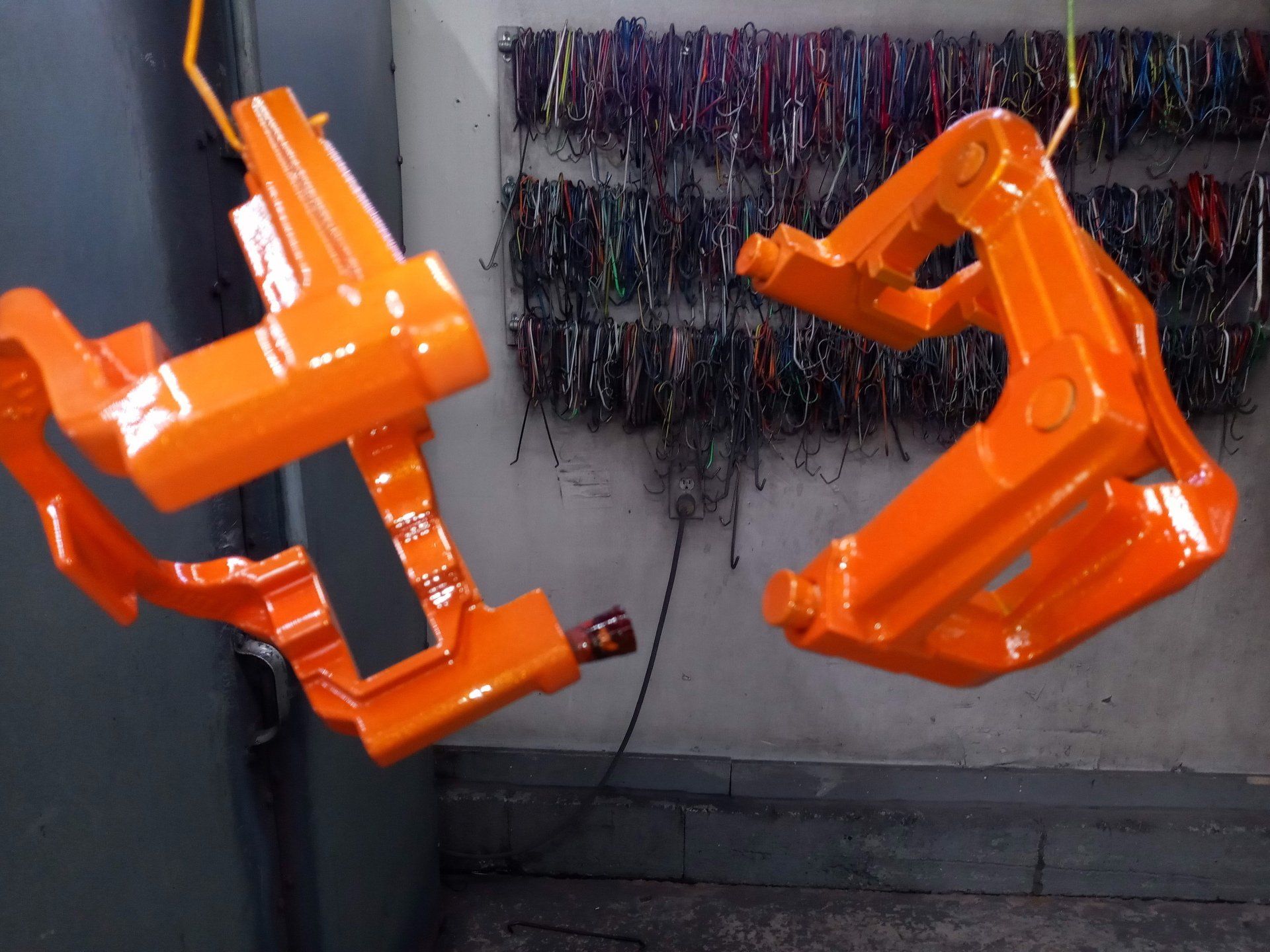

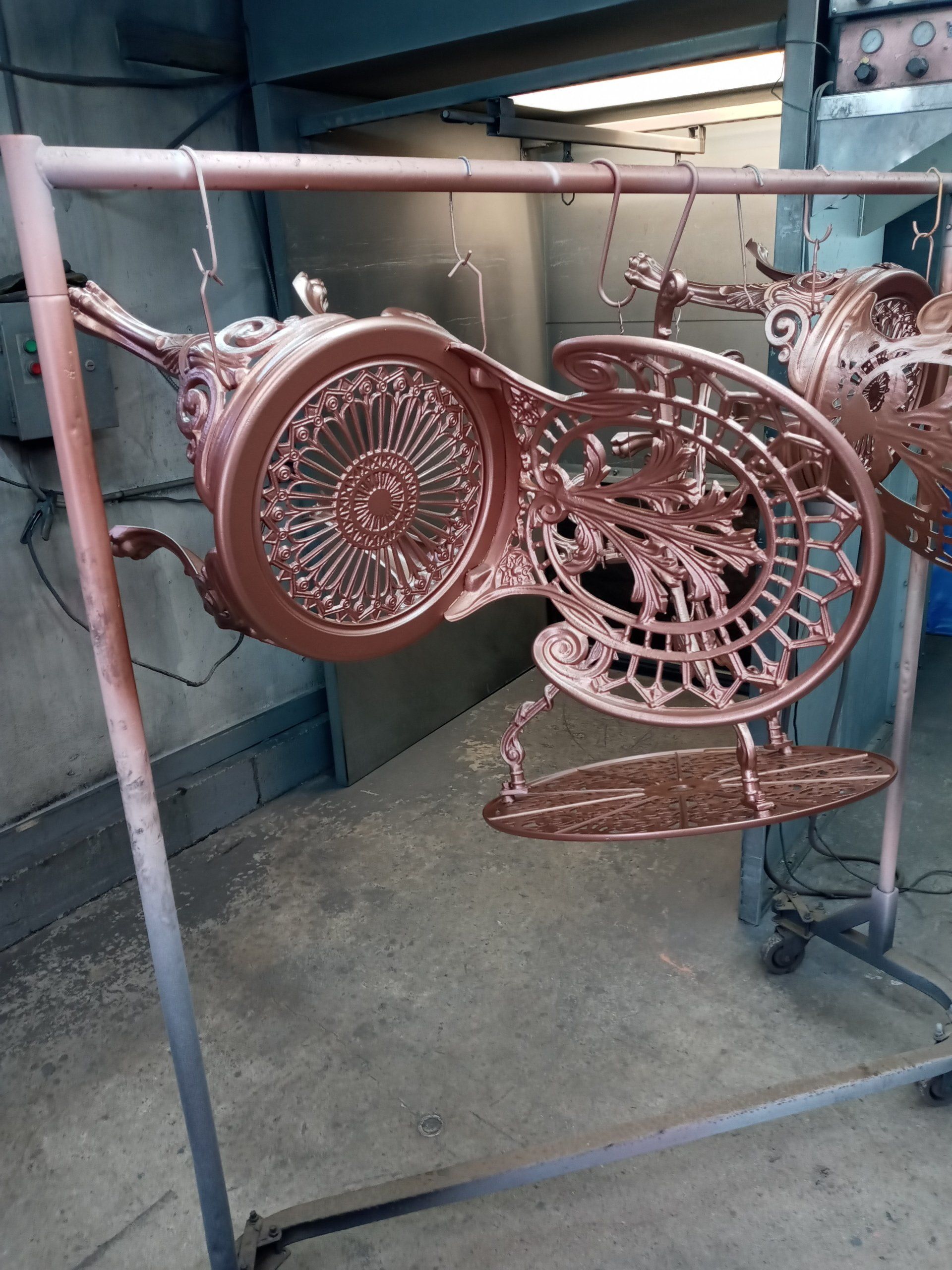

Unlike traditional paints, powder coating produces a hard, rigid finish that’s baked on to whatever surface it’s applied to. It’s an optimal finishing choice for metal products, including home furnishings and appliances, car and truck components, engines, bicycle frames and much more. Since it contains virtually no toxic compounds, a powder coating finish is an environmentally friendly way to imbue your items with added resilience and durability.

QUALITY SERVICES

When it comes to protecting investments like vehicles, appliances and metal furnishings, powder coating is a bet on longevity. Powder coating is an extremely durable finishing option—parts that are powder-coated are resistant to flaking, rubbing and corrosion, which might otherwise devalue them. We not only apply and cure powder coating for a high degree of protection, we can also customize the color to ensure your item comes out looking as beautiful as it is durable.