A Guide to Preparing Your Metal Surfaces for Powder Coating

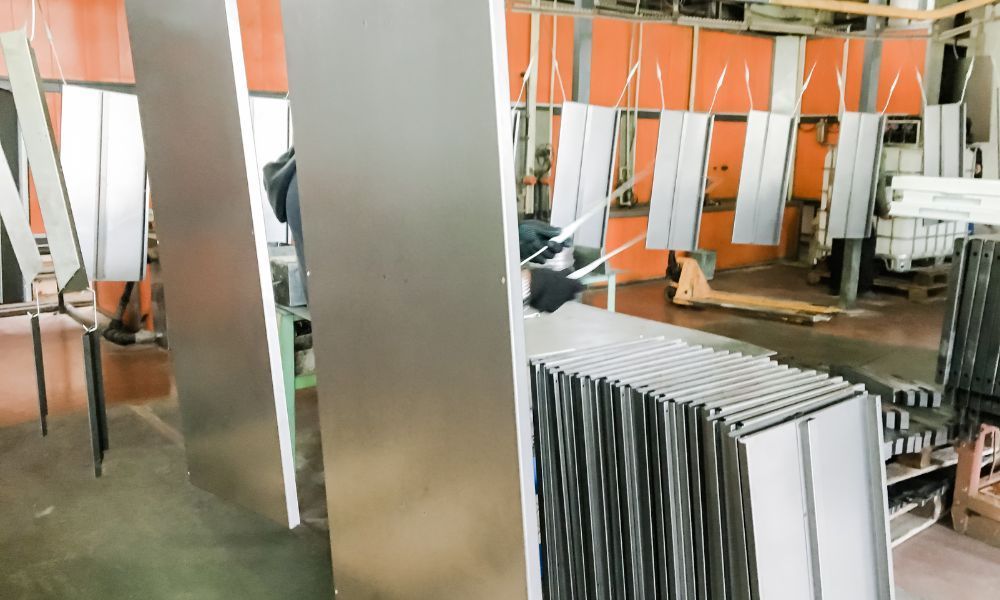

Executive Coast 2 Coast Powder Coating takes pride in providing top-tier powder coating services, delivering robust, efficient, and visually appealing finishes for a wide range of materials. Customer satisfaction is their primary goal, offering professional, environmentally friendly, and corrosion-resistant solutions tailored to unique project requirements. A significant aspect of achieving a flawless powder-coated finish is the proper preparation of the metal surface. This blog post will guide you through the crucial steps and best practices for surface preparation, ensuring optimal results for your powder-coated projects.

Metal surface preparation is a vital step in the powder coating process that cannot be overlooked. Failing to prepare the surface properly can lead to a lower-quality finish, reduced adhesion, and decreased durability.

By following these essential steps and implementing best practices for surface preparation, you can guarantee a long-lasting, visually appealing finish for your powder-coated projects. Join us as we break down the ins and outs of each step, highlighting the expertise and commitment to quality that Executive Coast 2 Coast Powder Coating brings to every project. Trust in their unparalleled services and let their professionals help you achieve exceptional results when preparing your metal surfaces for powder coating.

1. Cleaning the Surface

The first step in preparing a metal surface for powder coating is to thoroughly clean it, removing any dirt, grease, oils, and other contaminants that may impede proper adhesion. Below are the most commonly employed cleaning methods in this process:

- Degreasing: A chemical degreaser is applied to eliminate grease, oil, and other organic contaminants from the metal surface. The type of degreaser may vary depending on the specific material and contaminants present.

- Alkaline cleaning: This cleaning method uses an alkaline solution to remove dirt and debris from the metal surface. This process is particularly effective for cleaning steel and aluminum.

- Solvent cleaning: Solvent cleaning is the use of organic solvents to remove contaminants from the metal surface. It is especially useful for removing old paint or stubborn grease.

- Ultrasonic cleaning: This method uses high-frequency sound waves to agitate a liquid bath, creating micro cavitation bubbles that thoroughly clean the metal surface.

2. Removing Rust and Corrosion

Rust and corrosion can jeopardize the adhesion and durability of a powder-coated finish. Before applying the powder coating, it is imperative to eliminate any existing rust or corrosion from the metal surface through one or a combination of the following methods:

- Abrasive blasting: Also known as sandblasting or media blasting, this process uses high-pressure air to propel abrasive particles against the metal surface, effectively removing rust and corrosion.

- Chemical treatments: Acid-based solutions or rust removers can dissolve rust and corrosion on the metal surface. It is crucial to choose a suitable chemical treatment for the specific material to avoid causing any damage.

- Manual removal: For smaller or less intricate surfaces, using manual tools like wire brushes, sandpaper, or grinding discs may be a viable option for removing rust and corrosion.

3. Removing Old Paint or Coating

Before applying a new powder coating, it is necessary to strip away any old paint or coatings. A clean, bare metal surface ensures the best bond for the new powder coat. Here are some methods to achieve this:

- Chemical stripping: This method involves applying a chemical paint remover which dissolves the old paint, making it easier to remove with a wire brush or scraper.

- Abrasive blasting: As mentioned earlier, abrasive blasting not only removes rust and corrosion but can also be effective in stripping away old paint or coatings.

- Heat stripping: Applying heat to the metal surface causes the old paint or coating to blister, which can then be easily scraped off.

4. Surface Profiling and Etching

Creating an ideal surface texture and profile is crucial for enhanced powder coating adhesion. Surface profiling and etching techniques include the following:

- Abrasive blasting: In addition to removing rust and old paint, abrasive blasting can create the desired surface profile to ensure optimal powder coat adhesion.

- Chemical etching: Using acid-based solutions on specific materials, such as aluminum, can create a uniform etch for enhanced adhesion.

- Phosphate conversion coatings: Applying a phosphate coating to the metal surface can improve adhesion and provide additional corrosion protection for the substrate.

5. Masking and Protecting

While preparing the metal surface for powder coating, it is essential to protect certain areas that should not be coated. Masking is the process of covering these areas to prevent the powder coating from adhering. Here are some common masking techniques:

- Tape masking: Using heat-resistant tapes like Kapton or silicone to cover areas that need protection.

- Plug masking: Using rubber plugs or silicone plugs to cover holes or threaded areas.

- Custom masking: Creating custom masks to fit unique shapes or contours that require protection.

Proper masking and protecting ensure that only the intended areas are coated while avoiding any potential damage or contamination of the surface. Thus, it is a crucial step in the surface preparation process that ensures a high-quality powder-coated finish.

Conclusion

Successful powder coating begins with the proper preparation of the metal surface, taking into account each crucial step. By thoroughly cleaning the surface, removing rust and corrosion, eliminating old paint and coatings, and creating the ideal surface profile, you can achieve a beautiful, durable, and long-lasting finish.

Executive Coast 2 Coast Powder Coating is dedicated to providing top-tier metal powder coating in Marlboro that prioritizes impeccable surface preparation. Their expert knowledge and commitment to customer satisfaction guarantee a flawless result for every powder-coated project. Embrace the value of a well-prepared metal surface and experience the unmatched quality and durability of a finish!